Best Satisfaction Technology

Technology Which Enhances The Value Of Life

- HOME

- Mg Production Center

- Manufacturing Process

- Automatic System

Automatic System

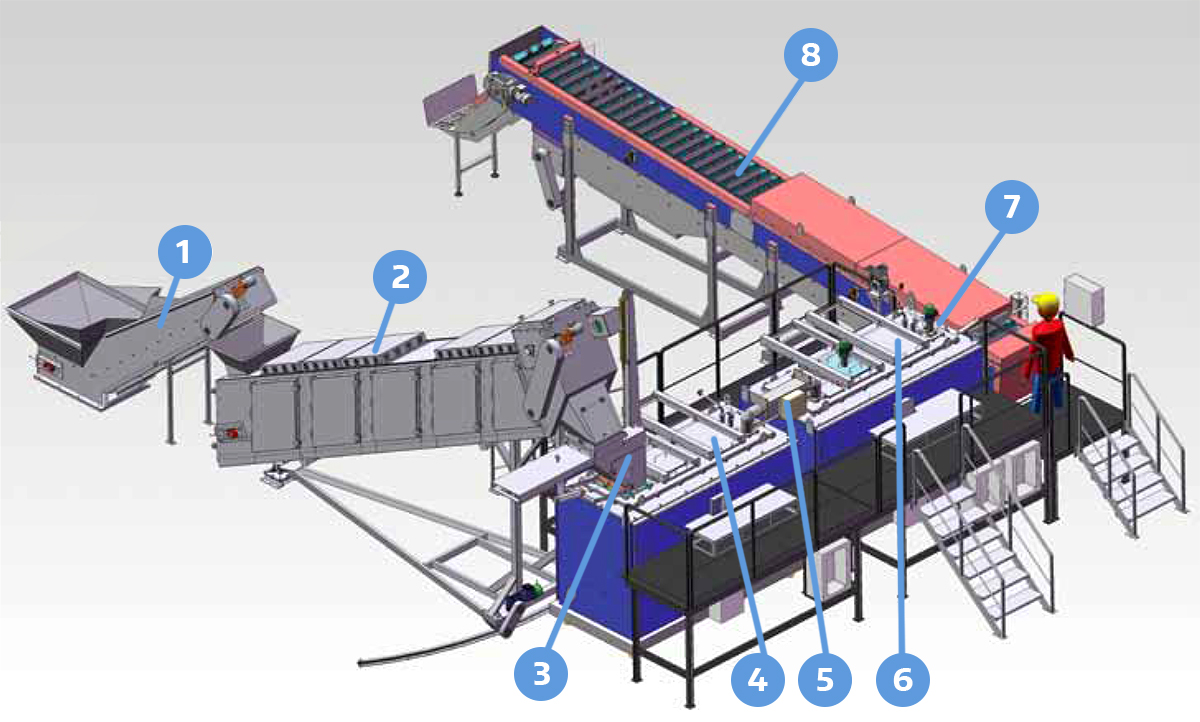

Equipment Name

Fluxless Magnesium Recycling System (EFRS-500)

Structure and Shape

Function of Each Part

-

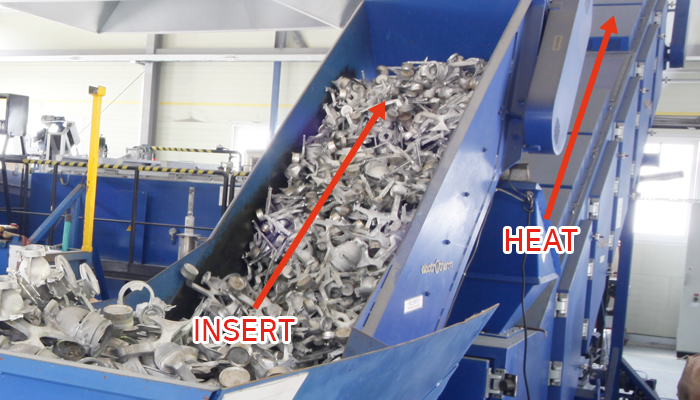

Input Conveyor : It automatically transfers the input magnesium scrap to the position

.

.

-

Pre-heated Conveyor : It preheats all the scraps before moving to the position

(melting furnace).

(melting furnace).

-

Material Input Device : It automatically transfers the preheated scrap to the position

(melting furnace).

(melting furnace).

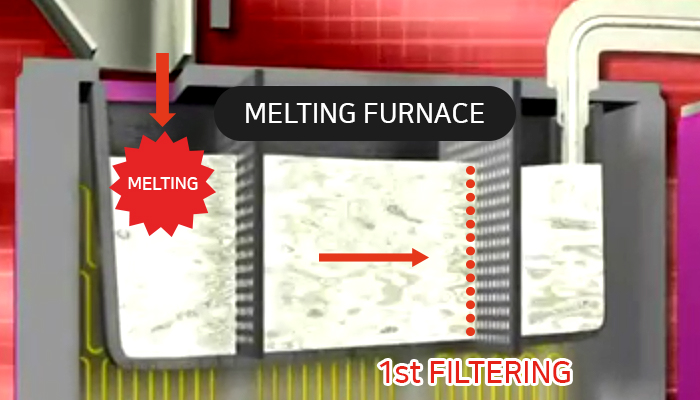

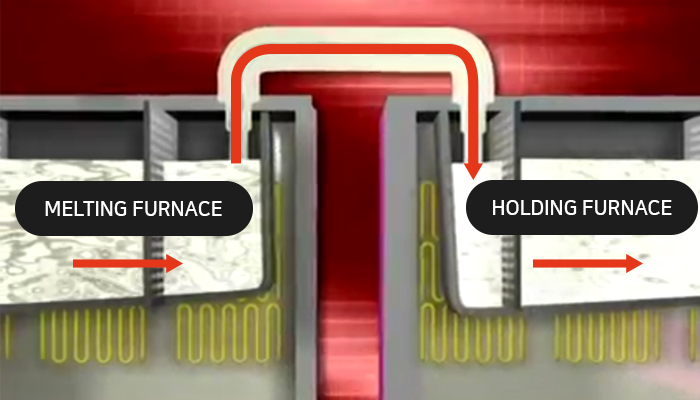

- Melting Furnace : As an electronic melting furnace to melt the input scrap, it removes impurities in the scrap through a primary filtration.

-

Transfer Siphon : It automatically transfers the melt and primarily filtered magnesium into the position

(holding furnace) to wait for casting.

(holding furnace) to wait for casting.

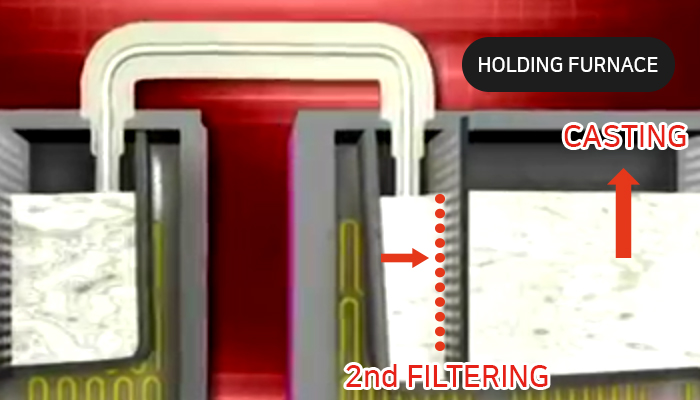

- Holding Furnace : As a place to store the liquid magnesium waiting for casting, it stores magnesium refined through the secondary filtration and other various measures.

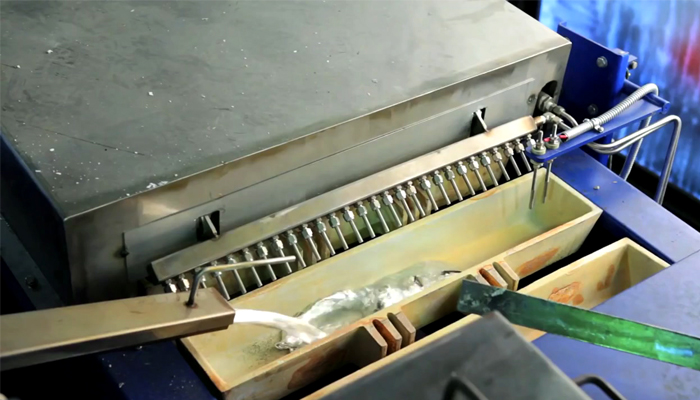

- Pump : It automatically transfer magnesium in liquid state to casting mold.

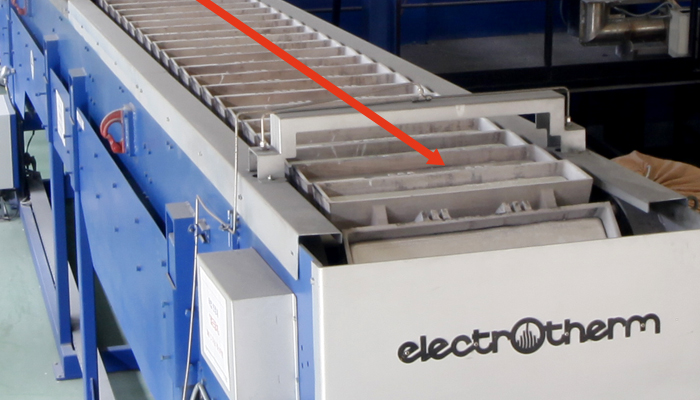

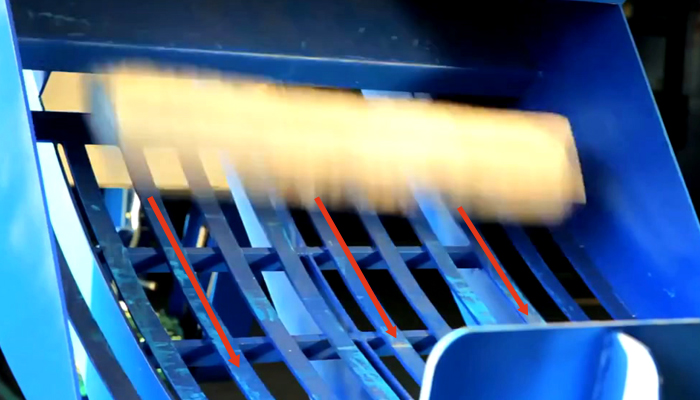

- Casting conveyor : It cools the cast ingot, and automatically transfers it after demolding.

Manufacturing process chart (Flowchart)

① Inputting and preheating scrap

② Melting scrap and primarily refining impurities in the scrap

③ Transferring the primarily refined magnesium into holding furnace

④ Degasifying and refining impurities secondarily

⑤ Casting ingot

⑥ Transferring/cooling ingot

⑦ Demolding ingot

⑧ Product packing